CAPA and Why Trackability Through ERP is the Lifeblood of Quality

Quality management and defect trackability is important for every successful manufacturer. For medical device manufacturing, however, the bar is set higher: not only is quality management important, it also is mandated by the Food and Drug Administration’s Corrective Action Preventive Action (CAPA) requirement (FDA 21 CFR 820.100).

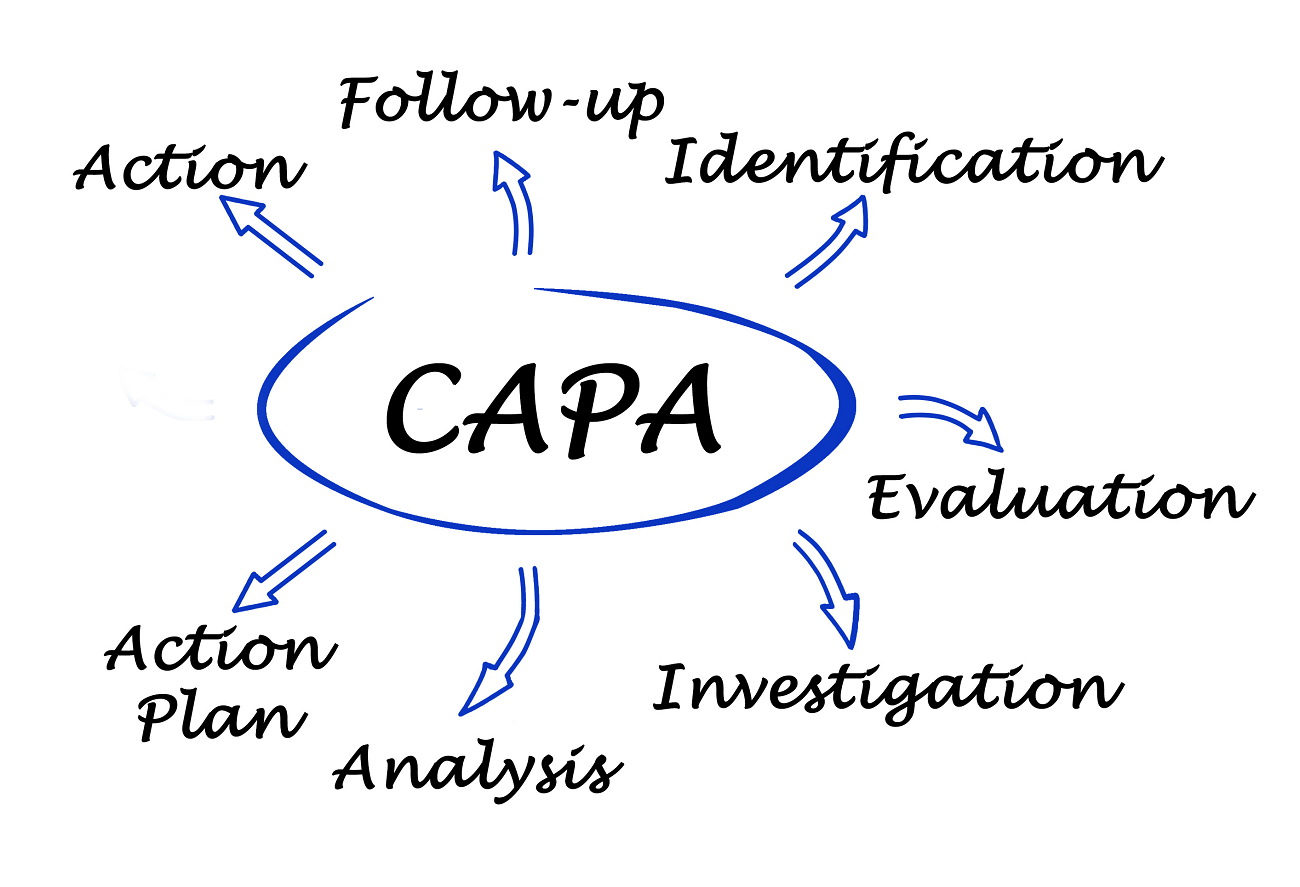

CAPA specifies that medical device manufacturers must take both corrective and preventative action against the root cause of any failure in their manufacturing process.

“Fortunately, failure is not experienced frequently in healthcare and medical devices,” notes Quality One International in a recent blog post, a manufacturing consultancy. “When failure does occur, we demand a rigorous process of investigation be initiated to identify why it occurred.”

Hence, CAPA.

CAPA is a good thing for consumers and anyone using a medical device, of course, but it also adds additional emphasis on tracking manufacturing output, identifying what’s gone wrong, and making sure it doesn’t happen again. This can be a considerable burden for medical device manufacturers unless they have the right systems in place.

Meeting CAPA Requirements with Better Trackability

The question is not whether the FDA will check if your company is following CAPA, but when. FDA inspections are part of doing business as a medical device manufacturer, and you should expect that the FDA will check in on whether you’re following CAPA every year or two if you manufacture a class II or class III medical device.

This means you need a good system in place for tracking defects, root cause and problem resolution, but also good documentation and trackability in your business processes so FDA auditing goes smoothly.

“Communication and procedures need to be clear-cut and trackable,” according to the McDonald Consulting Group, “with non-conformities documented, their root causes and investigations documented as well as outcomes and trends reported to management level for review.”

This level of trackability and oversight—necessary for all manufacturers but essential for those in the medical device market—can only come from having a centralized ERP system in place to monitor the activity of your operation end-to-end. While it might be tempting to manage the process with spreadsheets or a hodgepodge of systems, manufacturers will struggle to meet CAPA requirements if they don’t have a first-tier system for tracking and tracing every device built by their organization and the adjustments that are made when defects are discovered.

Advice for Better CAPA Implementation

For more than 10 years we’ve been helping manufacturers implement cloud ERP solutions to meet their quality and compliance needs. In addition to recommending an ERP solution that tracks a business end-to-end, we suggest the following for making sure your company has a fully developed and functional CAPA program.

First, develop your CAPA process early and make sure that you are following the FDA’s recommended guidelines. If you don’t know what is expected of your firm, you might not be in compliance.

Second, keep all of your company’s data centralized in an ERP system so you have better control and tracking. There shouldn’t be several systems for your business, just one: your ERP. Make that your nerve-center.

Third, work toward making your business and manufacturing processes as lean as possible so your company is easy to understand and audit. By keeping processes simple, you also make it easier to track and monitor how your company operates and spot problems that might be occurring.

Fourth, implement a risk management program early in your CAPA process. This should go without saying.

Fifth, focus on making sure you are clearly disambiguating symptoms from causes. Your definitions of problems need to be clean so you actually get at the root cause of problems.

Ideally every manufacturer should have quality management and solid trackability in place. For medical device manufacturers, though, this isn’t optional. So make sure you are up on CAPA and have good processes in place for tracking your manufacturing operation end-to-end.

For more information and to see the solution first hand join our FREE Weekly Webinar.

For more information regarding the Medical Device Manufacturing Solution.

For more information regarding the Pharmaceutical Manufacturing Solution.