ERP

October 02, 2020

The Easy Guide to ERP Acronyms

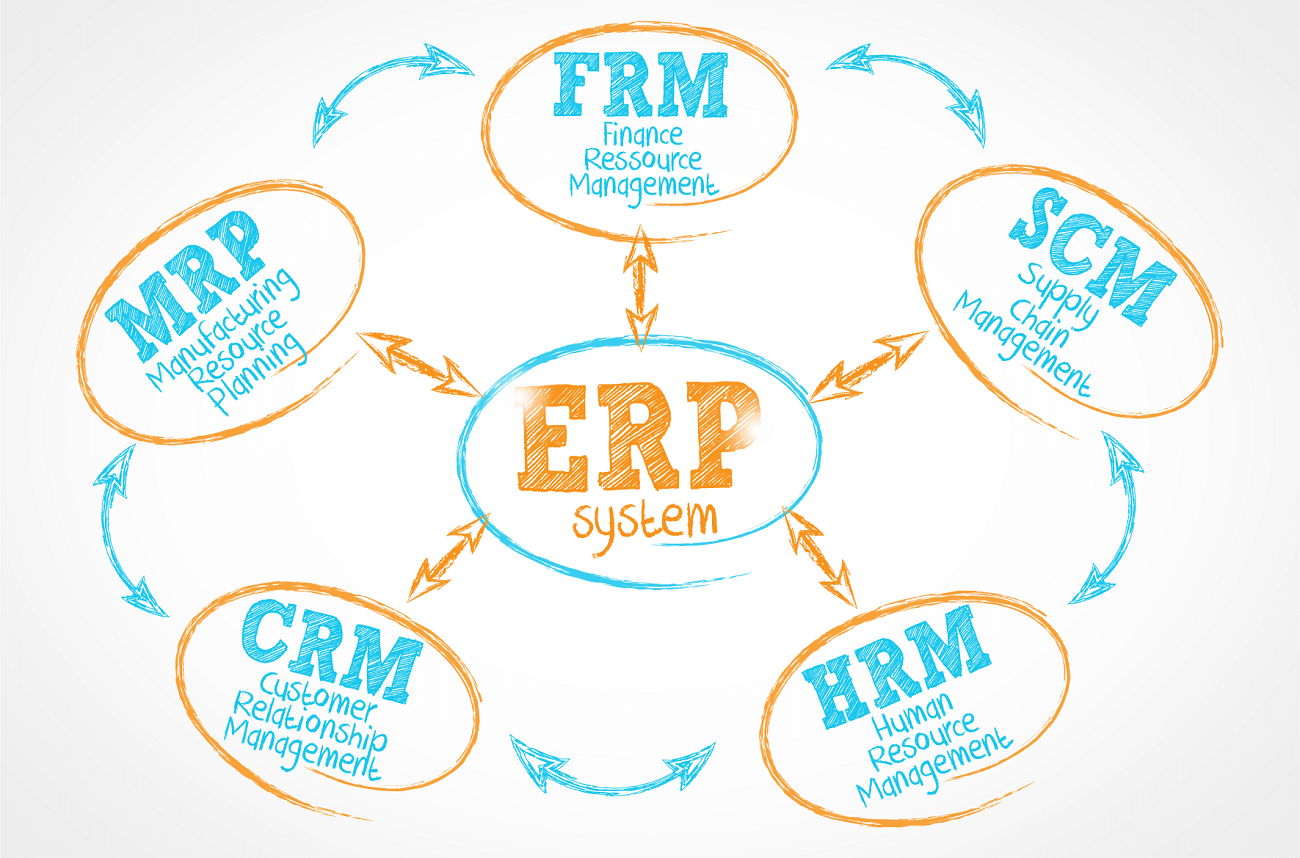

Most businesses in the market for an enterprise resource planning (ERP) solution will begin the process by doing some basic research. Unfortunately, the less tech-savvy among us might be overwhelmed by the number of acronyms related to ERP systems and technologies.

The process doesn't have to be daunting, however. Here’s a quick guide to some of the common acronyms you’ll run across when researching ERP solutions—in plain English.

Bill of Materials (BOM)

In manufacturing and production, a bill of materials (BOM) is essential for communicating information among partners and parties involved. It can include a list of materials, parts and quantities, and may also be used for different components of the manufacturing process.

A BOM is also commonly referred to as an ingredients list or recipe. Because it is so detailed, it is easily integrated with all the functions of the supply chain, making it an essential component of any ERP solution.

Some criteria exist for determining if an ERP solution is the right fit for a specific company's BOM needs. Any business in the market for an ERP system should ensure it can handle the following parameters and requirements related to its specific needs:

1) Tracking time and capacity

2) Level of detail for tracking component requirements

3) Support for BOMs that call out revisions of parts

4) Specification for multi-level product and sub-assembly BOMs

5) Ability to meet manufacturing lead times

6) Ability to create and maintain routings

7) Ability to store work instructions in a BOM or work order

8) Inclusion of templated BOMs for production, design and/or engineering

Warehouse Management Software (WMS)

WMS commonly refers to warehouse management systems, software and solutions. A WMS application supports and optimizes warehouse functionality, as well as distribution center management.

It is designed to facilitate management including daily planning, staffing, organization and control of available resources. A WMS system acts as a tool to help businesses quickly and efficiently meet customer demands on their specific supply chains and distribution channels.

The WMS is typically at the center of warehouse software, receiving orders directly from the ERP system. It then manages orders in a database, optimizes them and supplies them to conveyor control systems.

Many ERP systems have WMS capabilities (if you are running SAP Business One or SAP Business ByDesign there is LOXODO WMS) or integrations built into them, and not all businesses will require a stand-alone WMS system. Once again, it's important to evaluate your business needs related to WMS before choosing an ERP system.

Determine if you require:

1) Barcode scanning, RFID or mobile picking capabilities?

2) A specific type of inventory location tracking?

3) Specific integrations for purchase orders, accounting and reporting?

4) Warehouse layout planning?

5) A solution that provides contact and inventory management?

6) A specific type of e-commerce integration?

Supply Chain Management (SCM)

Effectively managing the supply chain is perhaps the most important goal for any business, particularly during these challenging times. Supply chain management (SCM) tracks the movement and storage of raw materials, work-in-process inventory and finished goods from origin to consumption.

Multi- and omni-channel networks and partners are all part of SCM, and must work together to create an efficient, competitive global infrastructure. SCM takes advantage of logistics, procurement, operations management, IT and marketing channels.

SCM is integrated in many ERP solutions and should be an important consideration when researching offerings. SCM within an ERP product may enable better efficiencies across departments, including reducing operating and overhead costs. It also has the potential to automate workflows and speed transactions and should also be able to scale up or down to accommodate changes in the business.

Material Requirements Planning (MRP)

Manufacturers need a material requirements planning (MRP) system, and in fact ERP started out as an MRP solution and grew from there many decades ago. These solutions typically handle production planning, scheduling and inventory control.

MRP ensures raw materials are available for production and that products are available to be delivered to customers. MRPs are also used to plan manufacturing and purchasing activities and to set delivery schedules.

An MRP solution may be stand-alone or included in an ERP system. Businesses will need to carefully evaluate their needs to determine which option will work for them. Considerations may include type of industry, global footprint and integration with larger functions like purchasing, marketing and finance.

Customer Relationship Management (CRM)

How a business manages interactions with current and potential customers falls under the purview of customer relationship management (CRM). CRM solutions typically compile data from a wider variety of communication channels and offer analysis to strengthen business relationships.

CRM offerings are designed to boost customer retention and drive sales. Many solutions use AI and analytics to better manage customer interactions. Most major ERP solutions embed CRM modules into their sales, distribution and customer service components.

While many great stand-alone CRM solutions exist, businesses get more from CRM when it is tied to all other aspects of a business. So the value proposition of CRM within ERP is stronger than standalone solutions that often only focus on sales.

Electronic Data Interchange (EDI)

The process of electronically exchanging business data that was once done on paper is known as electronic data interchange (EDI). Purchase orders, invoices and billing information all fall under this category.

EDI essentially sets standards to ensure businesses can seamlessly exchange different types of data, including providing rules for transmission, document format, message flow and software.

EDI and ERP must be interconnected seamlessly and efficiently. Your company's EDI solution should be a major factor in choosing the right ERP system. For more information, read our recent blog post The Critical Role of EDI in the Small and Mid-sized Business.

Omni-channel/Multi-channel Sales

Our last consideration is not an acronym but still an important part of the supply chain process and therefore a major consideration when choosing an ERP solution.

Multi-channel sales and marketing efforts typically use different channels to reach customers. An omni-channel sales and marketing approach integrates a variety of channels and lets the customer choose how to communicate and interact.

Read more in our earlier post 5 Benefits of Multichannel Distribution

Not all ERP systems will support omni-channel sales, so it's important to determine how your business approaches sales and marketing and find a solution compatible with your current and future efforts.

Researching ERP systems can be a major process, but having a basic understanding of the acronyms and components associated with ERP will go a long way toward helping you choose the proper system for your business.

For a more detailed glossary of ERP terms hop on over to our ERP Glossary page

If evaluating ERP still feels daunting, download our free guide, Understanding Cloud ERP for Non-IT Executives.